Cabin 68 Brewery Tour

Head Brewer Frank Reinhardt takes you on a guided tour of our brewery process.

Hello, folks! Welcome to the Cabin 68 Brewery. We are going to start over here with our grain storage. Most of our beers use Carolina Malt House, Carolina Gold, as the base malt. Malting is processing grains, such as barley, wheat, and rye to enhance their sugars for beer production. We have other specialty ingredients we use that are not grain, and those are all stored on the shelving.

We start out by taking our grain and putting it into the grinder, and it goes into the bins. We fill our cookpot with water and bring it up to a mash temperature of 150 degrees. (Mashing is the process of making a grain tea, which will be used to make the beer.) We have a basket with a screen in the bottom so that water can circulate through it. We put the basket down in the pot of hot water, and we pour our grain into the basket. We let the grain mash for 60 minutes. We then lauter the grain at 170 degrees and sparge for 60 minutes. (Sparging is a process of circulating the wort through the grain bed to filter out particulates.) After the lauter and sparge, the grain basket is hoisted up and allowed to drain. We rinse the grains with hot water and bring our wort level up to 42 gallons. (Wort is what you have before fermentation.) We then bring our temperature up to a boil, and depending on the recipe, the boil will last 60 to 90 minutes.

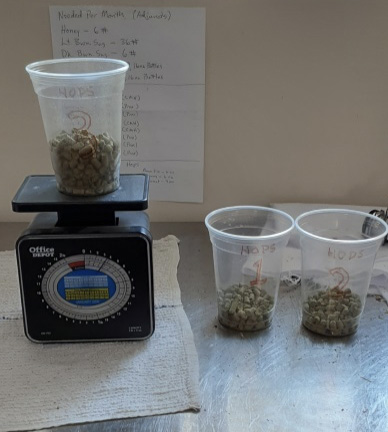

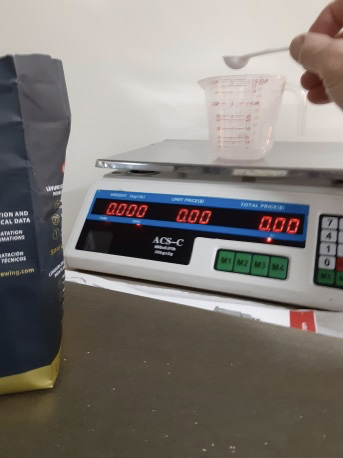

We measure out our hops and put these in cups for three hop additions. Most of our recipes use 3 hop additions. Hop addition number 1 is for bittering. Hop addition number 2 is for flavoring. Hop addition number 3 is for aroma. The hops are added at the start, middle, and finish of the boiling process. Once the boil is complete, we will plum everything up with our pump and run the wort through a series of chillers. We have two coil chillers and a plate chiller. At the start of our cooling process, the temperature of the wort goes from 212 degrees to around 100 degrees. When the temperature of the cooled wort cools down to 78 degrees, we change the plumbing connection to go to one of our conical fermenters. The wort is transferred to the conical fermenter, and after transfer is complete, we will measure our yeast and pitch it into the wort. Prior to this, we will take a specific gravity reading to see what the potential alcohol level will be.

It stays in the primary fermenter for a week and in the secondary fermenter for 1-2 weeks. With an IPA, it gets an extra week because of the dry hop process which makes it an IPA. After the fermentation is complete, we now have beer. At this point, we will take a final gravity reading and subtract it from the first reading to find out what our alcohol level is. We will take our beer and put it into kegs and then move it to our storage facility where we hook it up to a carbon dioxide conditioner to carbonate the beer. After three days at a specific pressure, the beer is ready to be served.